Description

Pressure reducer, DN25, stainless steel/PTFE-EPDM, FL, input pressure: max.25bar, output pressure: 2-10bar by End Automation EA

Pressure reducer, DN25, stainless steel/PTFE-EPDM, FL

input pressure: max.25bar, output pressure: 2-10bar

Spring-loaded pressure reducing valve in 3-piece body construction, completely made of stainless steel coupled with sealing materials such as NBR, EPDM, FKM and PTFE-coated membrane materials make this pressure reducer resistant to almost all flow media or environmental influences.

The pressure reducer is available in 3 housing sizes, which allow an exact design to the required pressure flow performance:

- Enclosure type 01 is designed for a power of up to 1,000l/h at a ?p of 1 bar

- Enclosure type 03 has a maximum pass of 4,000l/h also at a ?p of 1bar

- Enclosure type 05 with a flow rate of 7,500l/h, measured at a ?p of 1 bar

Springs tuned according to pressure levels ensure a high repeatability of the set output pressures. In the gas design, a damping element is also used, which reduces noise and vibrations. The pressure reducers are recognizable by the “-G” in the article number.

Specially developed for the food industry, the pressure reducer convinces by low death rooms. All parts in contact with the media can also be electropolished on request. The spring space is separated from the flow chamber by a membrane.

The pressure reducer can be sterilized with steam temperatures up to +150°C. For easy internal cleaning, the lid can be unscrewed. The O-ring sealing in front of the thread ensures that no products can be deposited in the threads.

The compact design allows installation even in confined spaces. The installation position is entirely up to you. Due to the high-gloss surface, installation in the direct field of view of the operator is possible and thus enables easy operation.

Due to the different types of connection available, easy integration into your pipe system is possible, e..B: threads, clamp or flange connections, welding ends according to DIN 11850-2 or ISO 4200, milk pipe fittings and much more.

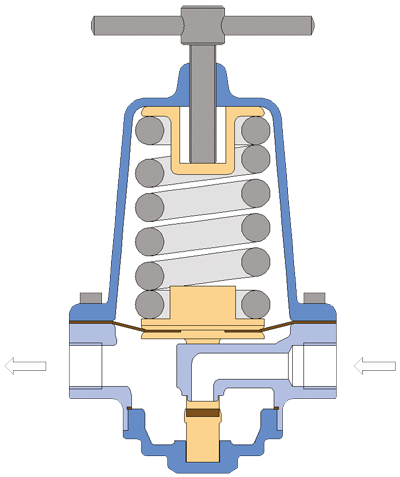

Functioning

The outgoing operating pressure is below the membrane and acts as a counterforce to the mounted and pre-tensioned spring package in the atmospherically ventilated housing. If the compressive force of the outgoing medium exceeds the spring force, the valve seat of the pressure reducer completes the flow.

This position is retained for as long as no picking takes place on the issue page. By removing the force below the membrane is reduced and the higher spring force has an opening effect on the valve seat seal.

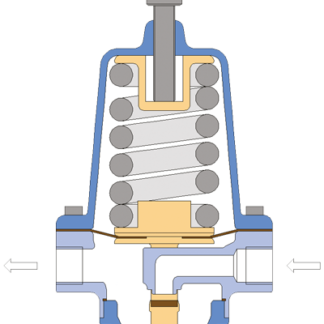

Setting

The pressure reducers are always set without flow, so the pressure gauge indicates the static pressure.

Increase in flow pressure:

Turn the adjustment screw clockwise

Reduction of flow pressure:

Turn the adjustment screw counterclockwise. Remove some medium and thereby reduce the pressure. Then tighten the adjustment screw to the desired pressure.

A pressure drop during media removal is normal, it is due to pressure loss.

Sizing

Pressure reducers must be dimensioned according to the expected flow rate (forevalues see DVGW worksheet W314). The flow rate at water should not exceed 2m/s. In practice, values between 1 and 2m/s are assumed.

For compressed air, the flow rates are a

maximum of 10m/s. We are happy to design the pressure reducer that is suitable for your application. Please fill in the valve data investigation sheet for pressure reducers.

Pressure Reducer DN25, stainless steel / PTFE-EPDM

Inlet pressure: max.25bar, outlet pressure: 2-10 b

FL= with flanges

seat-nozzle d= 16mm

with pressure gauge connection

Diaphragm: PTFE-coated/EPDM

seat-gasket: PTFE

Is this the right product for you?

email: sales@hvac‑sanitary.co.uk and we will make sure.